OJLC-600/1200 Computerized Hot Sealing and Cold Cutting Bag Making Machine

Performance and features:

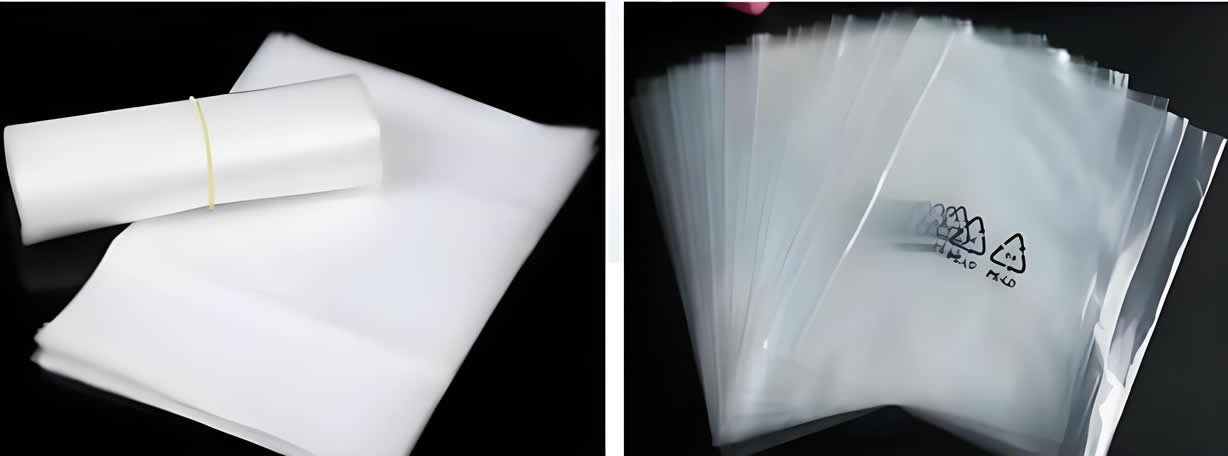

1.This machine is suitable for sealing and cutting high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP) plastic films. It is an equipment for producing plastic film vest bags and flat pockets.

2.This machine is equipped with a photoelectric automatic control feeding device, an automatic constant temperature control device, an electrostatic elimination device, an automatic counting and alarm device. The bag making process is fully automated, easy to operate, stable in performance, and firmly sealed. It is an economical and suitable sealing and cutting bag making equipment for large, medium, and small soft packaging enterprises.

Main technical parameters:

Model

OJLC-600

OJLC-800

OJLC-1000

OJLC-1200

Width

500mm

750mm

950mm

1150mm

Length

950mm

950mm

950mm

950mm

Speed

30-120 PCS/min

30-120 PCS/min

30-120 PCS/min

30-120 PCS/min

Number of articles

4

4

4

4

Motor power

1.5kw

1.5kw

1.5kw

1.5kw

Overall dimensions

3200x1150x1700mm

3200x1350x1700mm

3200x1550x1700mm

3400x1750x1700mm

Weight

750kg

850kg

900kg

1000kg

Heating power

4kw

5kw

6kw

6kw