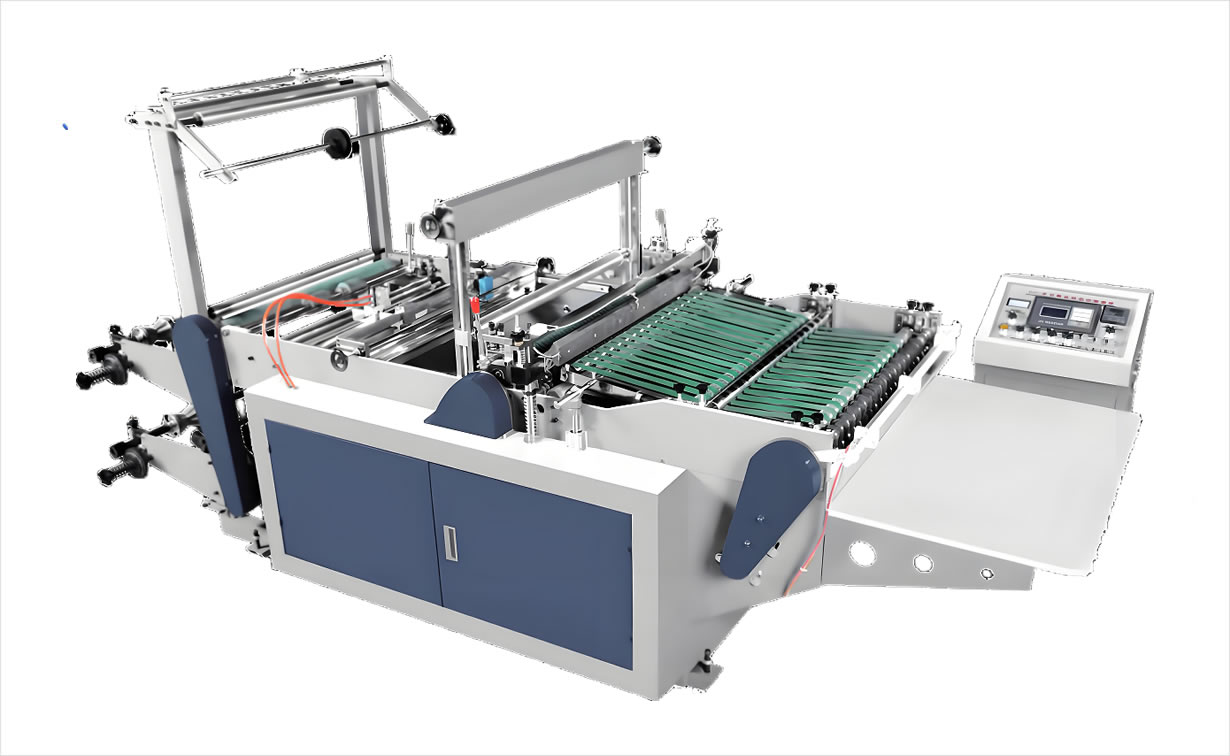

OJ-RQL800 edge sealing hot cutting bag making machine

Purpose:

This machine is suitable for hot cutting bags of printed and non printed plastic films such as BOPP OPP, PE, POF, etc. It is an ideal equipment for making express bags, sock bags, towel bags, bread bags, and jewelry bags.

Performance and features:

1.The whole machine is controlled by a microcomputer, and the material is dragged by a stepper motor.

2.Arbitrary fixed length, step size photoelectric tracking, accurate and stable, automatic shutdown when lost.

3.Automatically synchronize double-sided tape and drill holes.

4.utomatic counting and the ability to set any number of alarms.

5.Heat sealed lace and flat knife, automatic constant temperature, firm and smooth sealing, automatic breakage.

6.Low noise and fast speed.

Main technical parameters:

Machine model

OJ-RQL800

Maximum bag width

750mm

Maximum unwinding diameter

600m

Maximum bag making length

720mm

Working speed

20-200 PCS/min

Cutting accuracy

+0.15-0.5mm

Motor power

3.5kw

Machine weight

800kg

Machine dimensions

3600x1400x1700mm