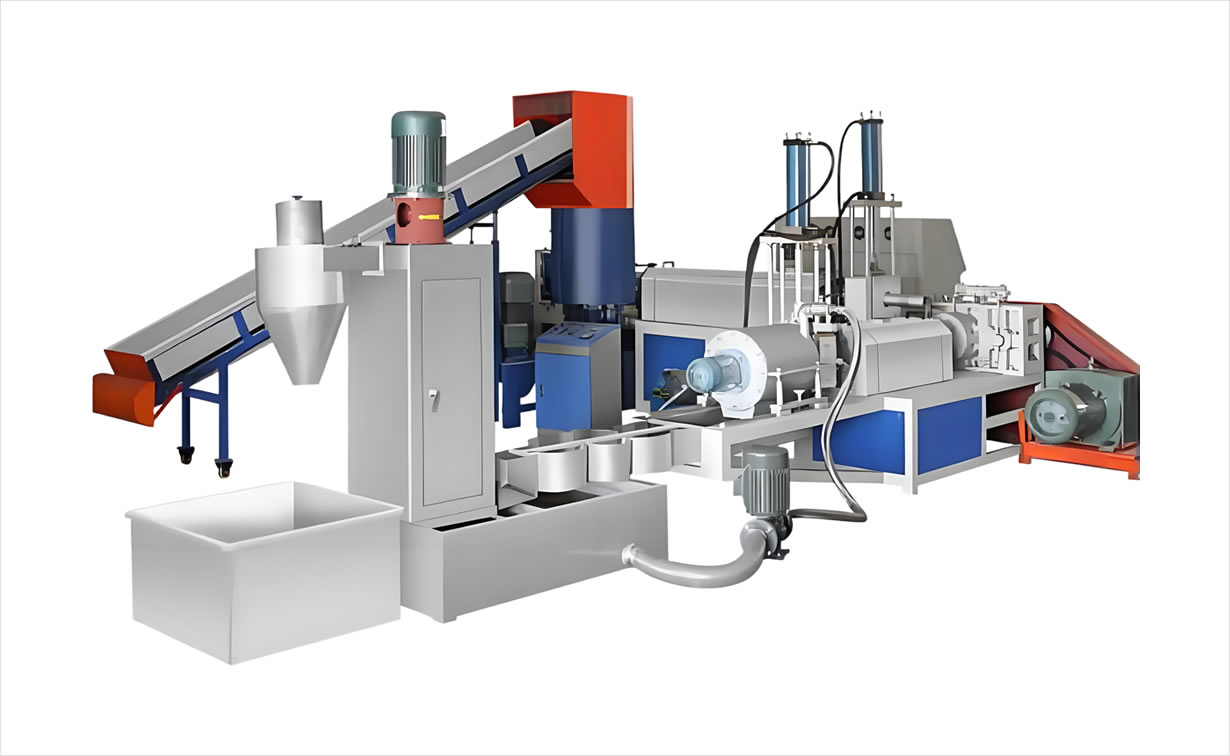

OJ High Speed Agglomerating Die Cutting Plastic Recycling Machine

Descriptions:

This plastic recycling machine is used to recycle waste plastics, like HDPE, LDPE, and PP, etc.;

It adopts conveyor belt feeding, and agglomerator crush plastic film into powder before material go into screw, in order to increase the productivity;

Hydraulic quick filter-screen-replacing unit on both stages, to save labour and time;

Water ring die cutting to cool the pellets effectively;

Vertical type dehydrator to remove moisture fast, as well as break the pellets apart;

Blower to dry the pellets again before it goes into the silo;

Specifications:

Belt conveyor

1.Belt length:4 m

2.Effective width:500mm

3.Motor power:1.5KW

4.Height: 2.5m

Agglomerator

Power of main motor: 37kw

Diameter of hopper: 800mm

Stage one: 140/22 Screw Extruder

1. Screw diameter:φ140mm

2. L/D:22:1

3. Motor power:55KW,frequency conversion

4. Screw and barrel are made of 38CrMoAlA and nitriding processed

5. Gear box: adopts #280 special hard tooth face gear box

6. Preheater: adopts high frequency ceramic heating

7. Hydraulic automatic screen changer, oil pump motor power: 2.2KW, manual control

8. Diameter of filter screen: 250mm×250mm

9. Dimension: 4200*1800*2300mm

Stage two: 130/10 Single Screw Extruder

1. Screw diameter:φ130mm

2. L/D: 10:1

3. Motor power:22KW,frequency conversion

4. Screw and barrel are made of 38CrMoAlA and nitriding processed

5. Gear box: adopts #200 special hard tooth face gear box

6. Preheater: adopts stainless steel heater heating

7. Hydraulic automatic screen changer, share one hydraulic station with 140/22.

8. Diameter of filter screen: 250mm×250mm

9. Capacity:250-300kg/h

10: Dimension: 2600*1600*1400mm

Cutting part:

Die face cutting device: underwater die-face cutter(2pcs of cutting blade)

Power of cutting motor: 1.5kw with inverter

Vertical dehydrator:

High speed vertical type dehydrator: stainless steel material

Power of dehydrator motor: 5.5kw

Dimension: 1800*1400*2200mm

Blower and silo:

Power of blower: 2,2kw

Capacity of silo: 1000kgs